- /

- China, Hubei

- around 7 working days

- 3,000 units one year

Oil tank transport semi trailer adopt carbon steel, aluminum alloy or stainless steel supplied by China state-owned steel enterprisers, and adopt BPW or China FUWA axle and BPW landing gear, ensure the overall quality

Oil tank use automatic submerged arc welding, argon arc welding, etc craft, adopt China top or European Standard or USA standard accessories, ensure oil tank accessory quality;

Making air tightness and water pressure test for every oil tank after finishing welding, at the same time, professional institutions supervision inspect the oil tank and issue oil tank inspection report. Also can introduce professional third-party inspection agencies, such as BV, TUV, SGS,etc. And in fact, our tank can pass Europe ADR Certificate.

3 axle oil transport semi trailer 50000 liters

Application and Brief Introduction

oil tank transport semi trailer is mainly used for transportation and storage of petroleum derivatives :gasoline, diesel, crude oil, lubricating oil, coal tar and other oil products.

Product Features of 3 axle oil transport semi trailer 50000 liters

FUWA or BPW 3 axles;

FUWA or BPW landing gear;

JOST Kingpin

Optional: China standard or European Standard accessory;

Optional: Carbon steel, aluminum alloy, stainless steel;

Main Parameter

GENERAL DESCRIPTION | |

Vehicle Brand | CLW |

Overall Dimension(L x W x H) | 12800x2500x3850mm |

GVW./Kerb Weight | 40000Kg/8200Kg. |

TANK BODY | |

Tank Shape | Elliptical or square round |

Tank Volume | 50000 liters |

Tank Material | 5mm Carbon steel , optional aluminum alloy or Stainless Steel |

End Cover and Baffles | 6mm end covers. One compartment with several inner baffles to reinforce the tank strength and prevent longitudinal surge during move. |

Outlet Valve | Size 4" ball valves fixed with cam-lock coupling in the discharge box |

Manhole | |

Necessary Accessories | One aluminum alloy subsea valves,one or two discharge valve, two pieces fuel pipes, one tool box; mobile guardrail, static grounding towing tape, rear climbing ladder, various connectors and dust caps |

| Option | European standard oil gas recovery system |

CHASSIS | |

Heavy duty reinforced chassis with reinforced axle. The tank's framework consists of two fabricated steel beams of high quality 16 Manganese steel. The two beams are fully welded all over their length on the tank. The beams are strongly connected with the cross members supporting the suspension and the kingpin upper coupler. | |

RUNNING GEAR | |

Axles | BPW/FUWA brand,etc. 3x13ton axles with double wheels |

Landing Legs | JOST/FUWA brand,etc. 28tons per pair |

Suspension System | Steel spring suspension or air bag suspension |

King Pin | JOST/FUWA brand,etc. 2inch or 3.5inch,bolted and welded type are optional |

Tyre No.&Spec. | 12 tires,11.00R20 steel wire tire or 12R22.5(tubeless vacuum tire) |

MUDGUARDS | |

Heavy duty mudguard rubber mud-flaps | |

BUMPERS | |

Side bumpers mounted between landing gear and first axle, rear bumper is European standard | |

ELECTRIC SYSTEM | |

24V lighting system,electrical socket for lighting,rear lamp with parking,direction,fog,reverse, 4 side lights | |

PAINTING | |

All steel plates and structure are blasted first, then painted with two anti-corrosive primer coats and two lever top. | |

Product detail

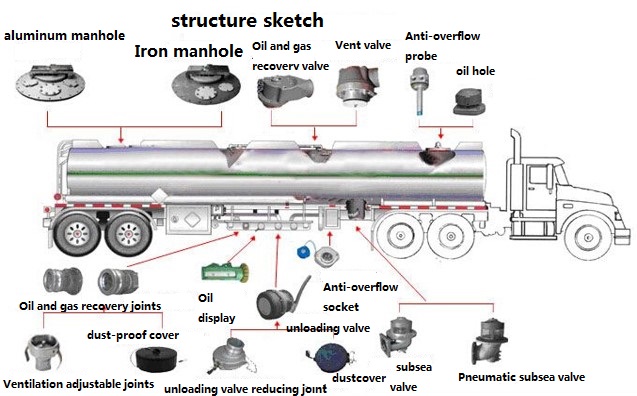

Oil tank transport semi trailer structure diagram

Batch exported oil tank transport semi trailer