- HOWO

- CHINA HUBEI

- around 30 working days

- 1000 unit

The ANFO mixing and charging machine truck features a teardrop-shaped hopper design, which improves the flowability of porous prilled ammonium nitrate within the hopper and reduces residual material left inside. The teardrop structure also enhances the strength and rigidity of the tank itself. While improving the overall performance of the ANFO mixing and charging machine truck, this design extends the hopper's service life by 30%.

ANFO mixing and charging machine truck

I. Technical Advantages

The ANFO mixing and charging machine truck offers the following advantages:

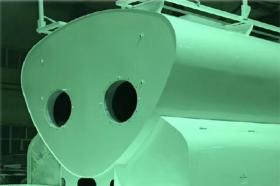

(1) Teardrop-shaped Hopper

The ANFO mixing and charging machine truck features a teardrop-shaped hopper design, which improves the flowability of porous prilled ammonium nitrate within the hopper and reduces residual material left inside. The teardrop structure also enhances the strength and rigidity of the tank itself. While improving the overall performance of the ANFO mixing and charging machine truck, this design extends the hopper's service life by 30%. It is well-suited for travel and operation on mine roads and has been successfully applied in multiple mining areas across China, including Xinjiang and Fujian.

Figure 1 Teardrop-shaped Hopper

Figure 1 Teardrop-shaped Hopper

The porous prilled ammonium nitrate hopper is made of 304 stainless steel and welded using argon arc

welding, meeting the requirements for material corrosion resistance and loading strength. The design process includes professional strength verification and calculations, and advanced manufacturing techniques are employed to fully ensure the quality of welding, installation, and service life.

(2) High-efficiency Mixing, Time-saving and Energy-efficient

The system combines advanced interrupted-tooth progressive spiral mixing and conveying technology with diesel injection technology (as shown in Figure 2). Before diesel is injected into the spiral for mixing with porous prilled ammonium nitrate, it undergoes pressurized injection treatment. After passing through the diesel injection device, the diesel forms a ring-shaped mist (as shown in Figure 3). The diesel atomization system ensures uniform spraying of diesel inside the inclined spiral. During the conveying process, porous prilled ammonium nitrate and diesel achieve highly efficient mixing, significantly improving mixing uniformity and efficiency. This enhances explosive performance while increasing unit production capacity, substantially improving the operational efficiency of the ANFO mixing and charging machine truck.

Figure 3 Injection Effect Diagram

(3) Pneumatic Vibration Reduces Material Accumulation

The hopper is equipped with a pneumatic vibration system, which effectively breaks material arches and ensures smooth flow of porous prilled ammonium nitrate into the bottom screw conveyor. This system also enables efficient clearance of residual material.

(4) Accurate Metering, Automatic and Intelligent Control

The electrical control system adopts Siemens PLC and Danfoss speed sensors, enabling PID closed-loop control of diesel flow according to process formulas, real-time monitoring of the metering screw motor speed, and synchronized PID closed-loop control of porous prilled ammonium nitrate and diesel. The speed sensor detects the rotational speed of the metering screw and feeds the data back to the control system. The metering screw serves as a precise conveying device; based on its rotational speed, the system automatically calculates the amount of ammonium nitrate being conveyed. The speed detection sensor for the metering screw provides 180 detection signals per revolution, ensuring high measurement accuracy. This allows the metering error to be controlled within ≤±2%, significantly improving the accuracy of explosive mixing ratios and enhancing overall blasting performance.

Porous prilled ammonium nitrate and diesel are conveyed according to the process ratio, thoroughly mixed within the mixing spiral, and then loaded into the blast hole. During charging, if the feed rate of porou

prilled ammonium nitrate is adjusted, the diesel feed rate automatically and intelligently matches the change without requiring the system to stop for manual reconfiguration. This effectively improves the accuracy of explosive mixing ratios and enhances overall blasting performance.

The system automatically measures the charge quantity for each individual blast hole. When the preset charge amount is reached, the system automatically stops, ensuring precise control of the charge loaded into each hole. The ammonium nitrate and diesel systems can be controlled independently. With a high degree of automation and simple operation, the system significantly reduces the labor intensity of operators and improves work efficiency. Mechanized charging also enhances the coupling between the explosive and the blast hole, significantly improving blasting results.

(5) Multi-level Interlock Protection, Safe and Reliable

The system is equipped with safety interlock protections such as flow interruption and hydraulic oil temperature monitoring. Multiple protective devices ensure the equipment operates normally and safely. The diesel delivery system is installed with an IFM flow meter to monitor diesel flow in real time. If the flow rate drops below the preset value, the system automatically triggers an alarm and shuts down, preventing dry running of the diesel pump.

(6) Remote Control Operation, Reduced Staffing and High Efficiency

The system is equipped with a handheld remote control device that allows direct adjustment of charge quantity, offering simple and convenient operation. The wireless remote control system connects to the PLC control system via wireless technology, enabling remote operation. Operators can use the remote to select blast hole numbers, adjust charge amounts, and start or stop charging. Only one operator is required to complete the charging process, reducing staffing by one person compared to operating from the cab.

(7) Independently Patented Thermal Insulation System

(8) The ANFO truck can be optionally equipped with an insulation system. The installed fuel-fired boiler insulation system enables multi-point monitoring and balanced temperature regulation. It can provide heating for the cab before the vehicle is started and keeps the diesel heated to prevent freezing of the fuel tank and pipelines. This ensures the ANFO truck can operate normally in ambient temperatures ranging from -50°C to +50°C.

(8) Strong Chassis Adaptability and Low Maintenance Cost

The vehicle chassis used for the ANFO mixing and charging machine truck features sufficient power, excellent adaptability, and low fuel consumption. It is capable of operating on rugged, muddy, winding, and slippery mine roads under harsh conditions. The vehicle has a maximum climbing ability of 35% and a minimum turning radius of 11 meters. For improved comfort, the cab is equipped with heating and air conditioning. The vehicle demonstrates high reliability and low maintenance costs.

(9) Wide Operating Range with Swing-Arm Spiral and High Charging Efficiency

The ANFO mixing and charging machine truck adopts a side-mounted spiral system with a 270° rotating capability. From each parking position, it can charge blast holes on both sides of the vehicle, enabling 3 to 5 holes to be charged per stop. Compared to traditional side-mounted spiral ANFO trucks, our model achieves a significantly wider charging coverage, greatly improving overall charging efficiency.

Our side-mounted spiral ANFO truck not only matches the charging range of top-mounted spiral models, but also offers greater operational convenience and higher safety. Due to the lower height of the discharge spiral (i.e., the swing arm), operators can more easily install and remove delivery hoses. This design enhances overall safety during swinging and charging operations compared to top-mounted spiral systems.

When using a 10×8m pattern for bench blasting, this ANFO truck can complete charging of 3 blast holes with a single parking position, as shown in the figure below.

(10) Seamless Integration of Charging and Blasting, Facilitating Blasting Operations

The ANFO mixing and charging machine truck is equipped with a user-friendly charging operation interface that displays key parameters such as hydraulic oil temperature, diesel flow rate, and ammonium nitrate feed volume. It can also statistically record and print information for each blast hole, including hole number and charge quantity. With comprehensive blasting report functions, it facilitates efficient data collection and statistical analysis for blasters.

The control system automatically records the corresponding hole pattern parameters (hole number, charge amount, hole depth), and features functions such as automatic data logging, storage, and upload.